Get This Report on Plastic Injection Molding

Wiki Article

The 15-Second Trick For Plastic Injection Molding

Table of ContentsThe Ultimate Guide To Plastic Injection MoldingPlastic Injection Molding - TruthsSome Ideas on Plastic Injection Molding You Need To KnowPlastic Injection Molding Fundamentals ExplainedThe Facts About Plastic Injection Molding Revealed

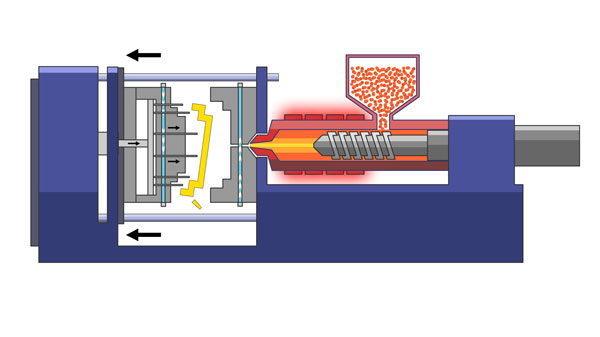

After that, the mould shuts as well as the process repeats. Pre-moulded or machined components can be placed into the tooth cavity while the mould is open, allowing the product infused in the next cycle to develop and solidify around them. This process is understood as Insert moulding and also allows solitary components to consist of several products.

Most polymers, sometimes referred to as resins, may be used, consisting of all thermoplastics, some thermosets, and some elastomers.

Readily available products include alloys or blends of previously created products, so item developers can choose the material with the finest collection of residential or commercial properties from a large selection. Major requirements for option of a product are the toughness as well as feature required for the last component, along with the price, but also each product has different parameters for moulding that must be taken into account.: 6 Various other considerations when choosing a shot moulding product consist of flexural modulus of elasticity, or the level to which a material can be bent without damages, along with warm deflection and also water absorption.

Plastic Injection Molding Fundamentals Explained

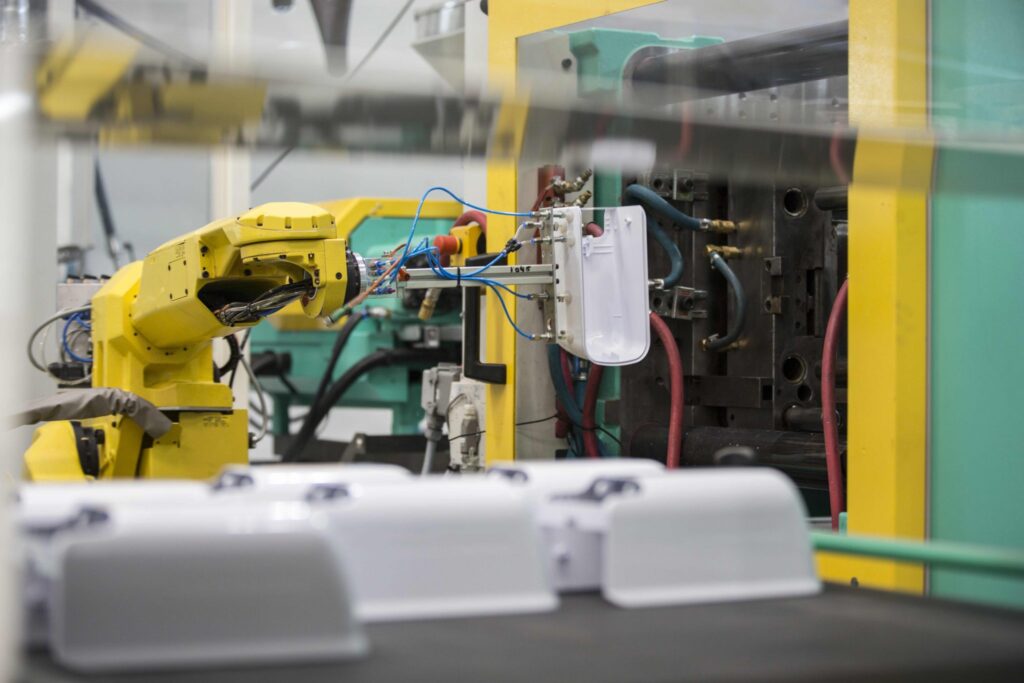

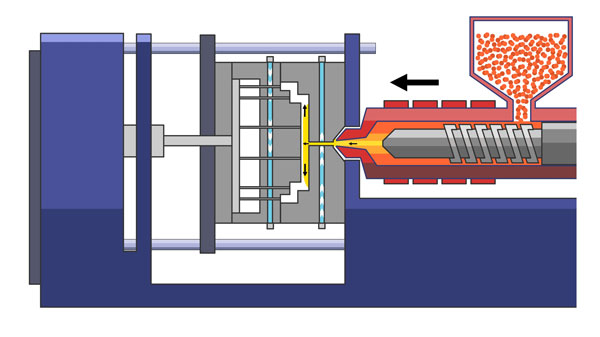

Applications consist of fastenings for securing as well as detaching outdoor-equipment webbing. Devices [modify] Injection moulding makers are composed of a material hopper, an injection ram or screw-type plunger, and a home heating unit.: 240 Additionally recognized as platens, they hold the moulds in which the components are shaped. Presses are rated by tonnage, which reveals the quantity of securing force that the equipment can exert.Tonnage can vary from much less than 5 bunches to over 9,000 bunches, with the greater figures made use of in fairly few manufacturing procedures. The overall clamp force required is established by the forecasted area of the component being moulded. This predicted location is multiplied by a clamp pressure of from 1.

2 heaps for each square centimetre of the predicted areas. As a guideline of thumb, 4 or 5 tons/in2 can be made use of for a lot of products. If the plastic material is really rigid, it requires even more injection stress to fill the mould, and also thus extra clamp tonnage to hold the mould closed.: 4344 The required force can likewise be identified by the product utilized and the dimension of the component.

Mould or die are the common terms made use of to describe the tool utilized to create plastic components in moulding. Given that moulds have hop over to these guys been expensive to manufacture, they were typically just utilized in mass manufacturing where thousands of components were being created.

7 Simple Techniques For Plastic Injection Molding

Shot moulding pass away with side pulls "A" side of die for 25% glass-filled acetal with 2 side draws. Shut up of removable insert in "A" side. "B" side of die with side pull actuators. Mould design [modify] Typical 2 plates tooling core as well as tooth cavity are inserts in a mould base "family mould" of 5 various parts The mould contains 2 main components, the shot mould (A plate) as well as the ejector mould (B plate).Plastic material enters the mould via a or entrance in the injection mould; the sprue bushing is to secure firmly versus the nozzle of the injection barrel of the moulding machine as well as to allow molten plastic to move from the barrel into the mould, also recognized as the navigate to these guys cavity.: 141 The sprue bushing directs the liquified plastic to the tooth cavity photos with networks that are machined into the faces of the An and also B plates - plastic injection molding.

(A) Sprue, (B)&(C)jogger and (D)entrances in real shot moulding product for playthings The quantity of material required to fill up the sprue, jogger and tooth cavities of a mould consists of a "shot". Trapped air in the mould can get away via air vents that are ground right into the parting line of the mould, or around ejector pins and slides that are somewhat smaller sized than the openings retaining them.

The air can even end up being so pressed that it ignites and sheds the bordering plastic material.: 147 To enable elimination of the moulded part from the mould, the mould features need to not overhang each other in the instructions that the mould opens up, unless components of the mould are created to move from between such overhangs when the mould opens up making use of elements called Lifters.

Not known Facts About Plastic Injection Molding

The coolant takes in heat from the mould (which has absorbed heat from the warm plastic) as well as keeps the mould at an appropriate temperature to strengthen the plastic at the most effective rate.: 86 To relieve maintenance and also airing vent, cavities and cores are separated right into pieces, called inserts, and sub-assemblies, also called inserts, blocks, or chase blocks.A lot more complicated components are developed utilizing much more complex moulds. These might have areas called slides, that action right into a tooth cavity perpendicular to the draw direction, to create overhanging component attributes. When the mould is opened, the slides are retreated from the plastic component by making use of fixed "angle pins" on the stationary mould fifty percent.

The part is then expelled as well as the mould closes. The closing activity of the mould causes the slides to move on along the angle pins.: 268 A mould can create several duplicates of the same components in a single "shot". The variety of "perceptions" in the pop over to these guys mould of that part is usually improperly referred to as cavitation.

All about Plastic Injection Molding

This system can enable manufacturing of one-piece tires and also wheels. Two-shot or multi-shot moulds are developed to "overmould" within a single moulding cycle as well as have to be refined on specialised injection moulding devices with 2 or even more injection systems. This procedure is in fact a shot moulding process carried out two times and also for that reason has a much smaller margin of error.

Report this wiki page